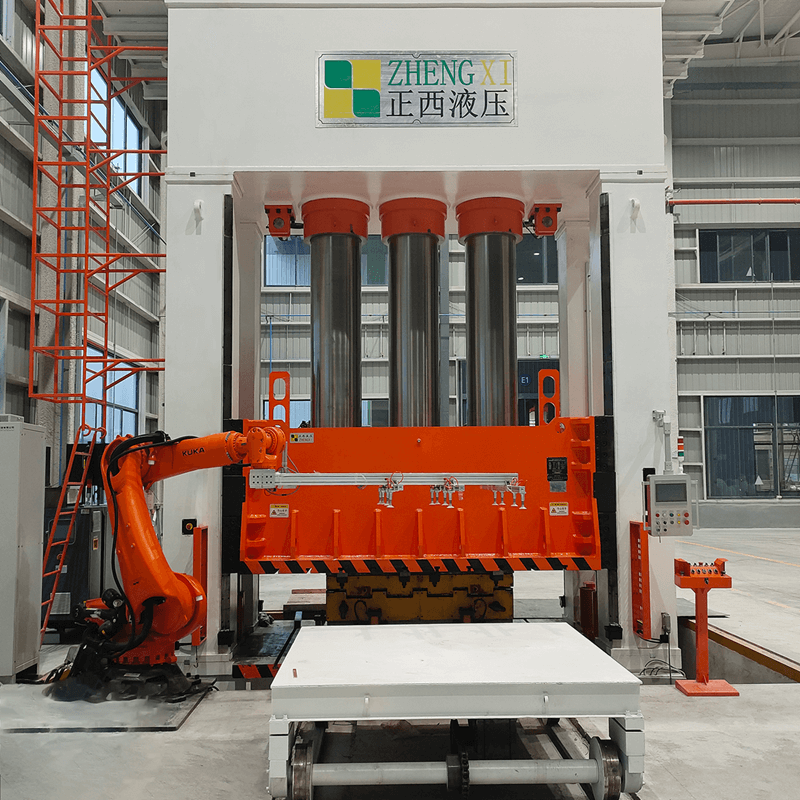

ZHENGXI SMC BMC Hydraulic Press, also called a hydraulic composites molding press, is applied to compress composite materials such as SMC, BMC, FRP, GRP, etc. Our SMC forming presses and presses offer the composite industry superior production capabilities and repair and upgrade options. We are supplying new custom hydraulic molding presses, and ZHENGXI also provides a comprehensive list of repair and upgrade options for existing compression molding presses of all makes and models. Our hydraulic molding presses produce various innovative automotive, aerospace, industrial, etc.

Features of SMC BMC Hydraulic Press

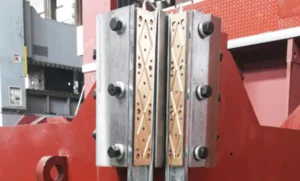

- It is mainly used for the integral forming of thermosetting (FRP) plastics and thermoplastic products. Suitable for forming SMC, BMC, DMC, GMT, and other bulks and sheets.

- The hydraulic system is installed on top with a maintenance platform, is environmentally friendly, has low noise, and is easy to maintain.

- Multiple-stage slow-speed pressure is forming, and there is a reasonable reserved exhaust time.

- The function of a high-pressure, slow-opening mold is suitable for high-pressure products.

- Quick response of the system, numerical control system.

Main Body

The design of the whole machine adopts computer optimization design and analysis with finite elements. The strength and rigidity of the equipment are good, and the appearance is good. All machine body parts are welded with high-quality steel mill Q345B steel plate, which is welded with carbon dioxide to ensure the welding quality.

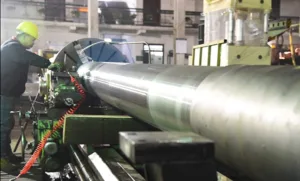

Pillar

The guide columns (pillars) will be made of C45 hot forging steel and have a hard chrome coating with a thickness of 0.08mm. And do hardening and tempering treatment. The guide sleeve adopts a copper guide sleeve, which is more wear-resistant and improves the machine’s stability.

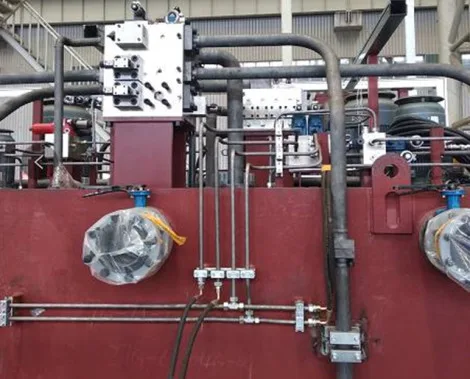

Hydraulic System

- The oil tank has been set with a forced cooling filtering system(industrial plate-type water cooling device, cooling by circulating water, oil temperature ≤55℃,make sure machine can operate steadily for 24 hours.)

- The hydraulic system adopts an integrated cartridge valve control system with fast response speed and high transmission efficiency.

- The oil tank has an air filter to communicate with the outside to ensure the hydraulic oil is not polluted.

- The connection between the filling valve and the fuel tank uses a flexible joint to prevent vibration from transmitting to the fuel tank and completely solve the oil leakage problem.

Applications of SMC BMC Hydraulic Press

This press machine is mainly suitable for composite material molding. The equipment has good system rigidity and high precision, high life and high reliability. The process for hot press forming meets 3 shifts/day production.